Ariadne 2016-2024

- 15 minutes read - 3147 words

Review of the past eight years

A little over eight years ago, in October 2016, I signed the deed of sale in Hamburg, which transferred Ariadne to me.

During the past eight years, all sorts of things have happened and, as is normal, not everything has been all sunshine and rainbows.

Many people are probably wondering - like me in this story - whether there was any point in this, but it is usually not worth thinking about when talking about hobbies. At least not terribly seriously. As Warren Zevon (R.I.P.) said in his last TV appearance “Enjoy every sandwich”.

Making the deal

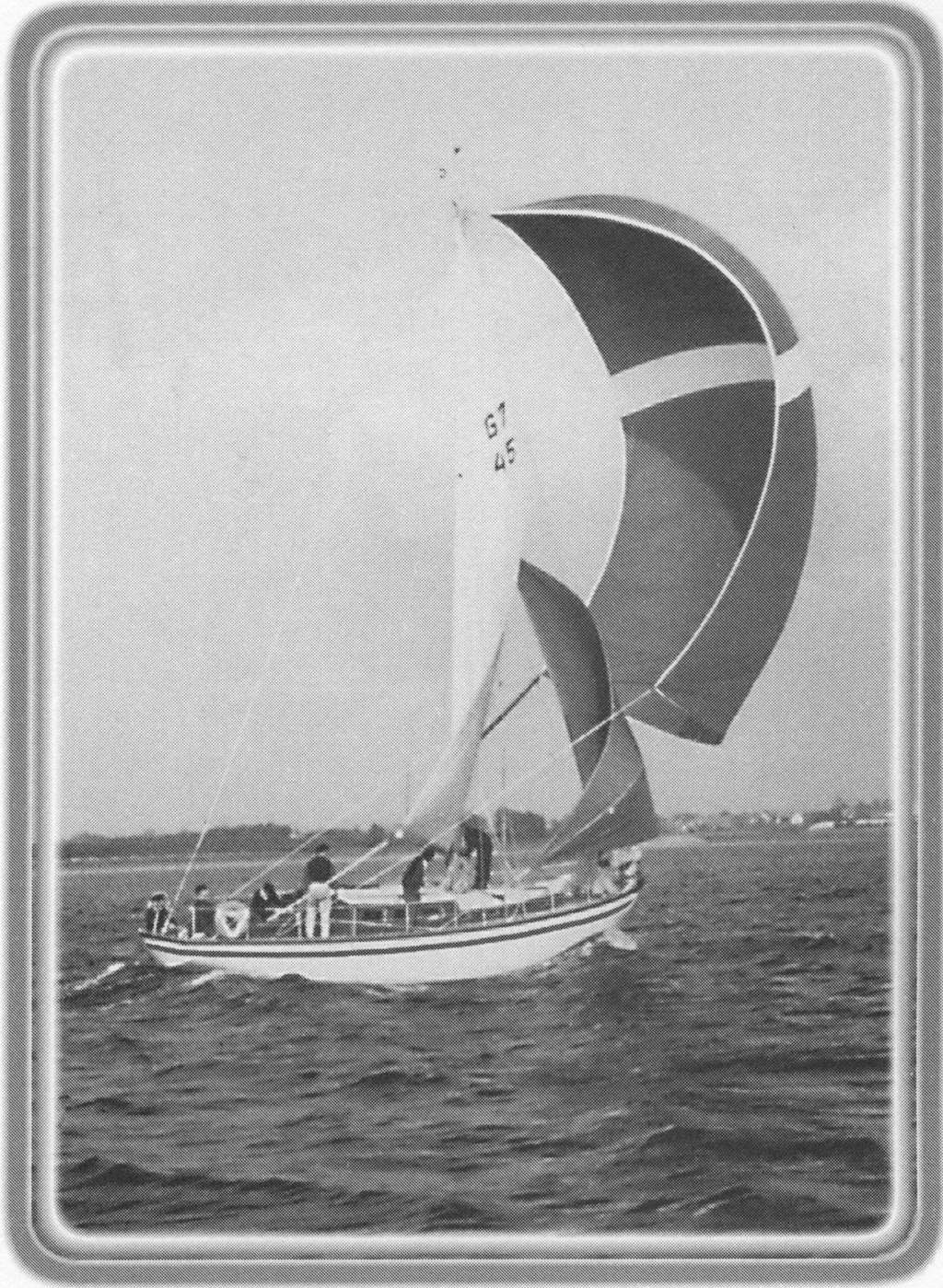

I signed the deed of sale for Ariadne in October 2016, a little over 8 years ago. Ariadne strategic information: Keel laid 1964 length 12.55m width 3.56m depth 1.80 weight 11,000kg Top rig, mainsail 33m2, genoa 42m2 Steel hull, thickness 3.5mm-4.5mm, keel area 5.0mm-6.0mm Teak deck on double plywood, total thickness 45mm, built 1997 Engine Mercedes-Benz OM636, 42hp

The seller was Ariadne’s second owner, Mr. Hartwig Breuss. He was over 80 years old and had bought Ariadne from his friend, Horst Vogelier, who had Ariadne built in 1964. Horst had a camera shop in Hamburg and thanks to that, Ariadne’s first launch was recorded on a film strip that was digitized by Hillmar, Hartwig’s son. The builder was the designer’s shipyard, Paul Böhling Yacht- und Bootswerft in Hamburg. The construction was financed by sending money to the shipyard in bags on several occasions. Ariadne’s home port was the SVAOe in Wedel, Hamburg, and Ariadne also wintered in the first completed shed in the harbor. In 1965, Ariadne’s stern was renovated to be more functional at the Mathiessen & Paulsen shipyard, where the bilge was raised, the stern was given “glove compartments” and the stern winch pair got one more pair. The first owner probably would not have sold Ariadne in the late 60s if his camera shop had not gone bankrupt.

In the deed of sale I signed, it was agreed that Ariadne would be lifted up to her old place in the shed in Hamburg and the seller would also do a spring overhaul, launch and rigging. We also verbally agreed that I would get pilotage assistance in Kiel, from where I thought we would sail Ariadne home in early summer 2017.

Hamburg

Although we agreed in the contract of sale that Ariadne would be ready to sail by the seller in spring 2017, I ended up making a few repair trips to Hamburg in spring 2017. Since flying was out of the question due to the freezing of tools and supplies, the only options were a car and Finnlines to Travemunde or the Swedish ship to Stockholm. Driving is almost a rest for us, so I ended up taking the Turku-Stockholm Swedish ferry, i.e. the morning ferry to Stockholm, and from there overnight on the E4 highway through Denmark to Hamburg, where I would arrive the next afternoon. I stayed in the Breuss home, in the office space downstairs where the service was excellent, there was even a fridge with a well-stocked beer supply, and when I left for Ariadne in the morning, snacks and a full thermos of coffee were waiting in the hallway. The spring renovation itself went smoothly in the warm hall, as soon as I learned that the sanders had their own days reserved. During the spring renovation of the still unknown Ariadne, most of the time was spent studying the ship and its structure. Since Bremen was close to Hamburg (about a two-hour drive), I visited there a few times because it had SVB, the most versatile and comprehensive boat supply store. There were boat supply stores in Hamburg too, but SVB clearly won with its selection.

During the spring, the crew for the Kiel-Hanko sailing was confirmed, there would be six of us: me, Jari, Piccu, Markku, Aimo and his son Tuomas. On my last trip to Hamburg, I had a carload of equipment with me, including a 45L day tank and an electric transfer pump, a new Webasto, a renovated genoa and mainsail, and everything else possible. The launch was on April 20th at 8 am and the mast was raised in the afternoon, when the tide was high enough to raise the mast. The return trip home on the boat began the next day, and before that, a check-up trip to Ariadne, which was resting on the pier, perhaps foreshadowed future problems because the seawater pump was dripping a little seawater.

To home waters

I made my last trip to Hamburg by plane on May 1st and spent a couple of days driving a rental car looking for provisions so that I wouldn’t have to buy everything from Kiel, where Jari, Piccu, Markku, Aimo, and Tuomas were arriving on Friday, May 5th. Olav, Hartwig’s son, and I prepared to “sail” to Ariadne’s Kiel.

Two days were reserved for the Hamburg-Kiel sailing, as the Kiel Canal is about 60 nautical miles long. We set off on Wednesday, May 3rd. The sailing schedule was changed just half an hour after leaving Hamburg because the engine’s seawater pump started leaking heavily. I replaced it with an electric gear pump that I had thought of for fuel - but left the old one in place at the end of the crankshaft - while Olav sailed towards Brunsbuttel. The first day’s sailing ended prematurely right in Brunsbuttel when the engine stopped midway with a noise worth about 10,000 euros. Fortunately, my fears turned out to be unfounded, as the cause was only an old seawater pump that had cut out. However, this investigation and repair work took so long that we spent the night in Brunsbuttel. During the next day, the engine had problems with fuel supply, but we reached Kiel late in the afternoon.

The crew arrived on Friday morning and the next 24 hours were spent making purchases and ensuring fuel supply. We solved this by pumping fuel from the main tank near the surface with a tank-mounted oil change pump - capacity 4 liters - and pouring clean fuel into the 45L day tank I brought, an average of four to five pumps per session. We would repeat this pumping operation along the way as needed.

We left Kiel on Saturday 6.5. in the early afternoon in a light wind. After sailing overnight, we ended up in Hassle, Bornholm, after cruising in a brisk wind - a shocking angle of leeward!. The program included a visit to the store, installing the heater and eating at a local beach bar.

The trip continued the next morning and one significant memorable moment is arriving between the coast of Öland and Sweden at night when I was on watch with Markku. The wind was between east and southeast, very brisk because the speed was between 10 knots. The rudder was heavy, Marku, who was at the helm, noticed this from his panting and he advised us to pull the genoa in to lighten the rudder. The big genoa was really annoying, though, and I suggested that we roll it in to reduce the square footage. That also turned out to be impossible. The reason was the second genoa tack that wrapped around the genoa with the helmsman’s tack when it was rolled in. Fortunately, the wind died down and in the morning we passed Kalmar in calm and cool weather, a few degrees above zero.

Another memorable moment is Landsort, where we stopped next after leaving Hassle. The port staff heated up the sauna for us and after a restaurant tour we continued our journey. Early in the night, a Swedish navy ship followed us - probably because we were sailing without lights - and Piccu chatted with them on VHF and finally they wished us a good trip.

We arrived in Hanko on Friday, May 12th and the program included a sauna at the Baltic Sea Gate and dinner at Origo. Piccu, Markku and Jari switched to rubber dinghies on Saturday and I sailed Ariadne to Inkoo with Aimo and Tuomas on May 14th. As I wrote in bule 2017: “a hell of a trip”.

Renovations

With Ariadne, Johanna’s woodwork partly changed to steelwork. After the first Finnish winter, I managed to find a hole below the waterline; I tapped off the rust from the inside and the chisel went through the bottom. So a stick welding machine was on the shopping list. That’s how the Italian miracle was chosen, which threw in the towel two years later. Wisely informed, I ended up with Kemppi and I have no regrets other than not buying the weld in question right away. Measuring the thickness of the hull on a steel boat is an everyday occurrence and I got a German ultrasonic steel thickness gauge from a coworker for that. It has been an invaluable help when checking the condition of the hull and it is currently starting to be completely worn out. Here are some renovations over the past eight years:

Through-hull fittings

All of Ariadne’s through-hull fittings were replaced with Truedesign through-hull fittings and faucets, which are made of composite. Bronze through-hull fittings and valves were also considered, but I didn’t end up with them due to corrosion. I cut out each through-hull fitting with a hacksaw and welded replacement pieces to them because the new through-hull fittings are not in the same places. The valves have limit switches and I installed indicator lights on them so you don’t have to remember the valve positions.

Hull

Steel boats rust on the inside, and that’s also the case with Ariadne. I’ve replaced a couple of square meters of steel in the hull. Some of it has gone to repairing thin spots and some to new parts. For example, the bilge from the propeller shaft (approx. 80 cm) received new 4mm steel on both sides of the hull where bilge water had been sitting for decades. The hull had thinned to 2mm thick at worst in those spots. Now it’s 4mm.

Ariadne has a large fuel tank. It’s part of the hull and its volume is 300L. Two small holes were found in its bottom, which is also the lower part of the keel, and I spent quite a while repairing them in 2019. The most visible changes to the hull are probably the lowering of the bilge. The bilge in front of the fuel tank is a little over a meter deep in relation to the keel and the shallowest part is half that, meaning the lower part is a closed space equipped with inspection hatches. The reason for the renovation was the impossibility of cleaning, drying and painting the deep bilge.

Bow thruster

Ariadne is a 12.55m long long-keeled boat and turning it in a narrow harbor basin requires nerves and experience-based skills, not to mention what it requires to reverse it in a controlled manner. I am already used to maneuvering, although in the early summers I had to leave an excellent berth out of the way several times when entering the harbor because it was either in too narrow a place, the wind was capricious or an oncoming boater offering advice ruined the approach. I had been thinking for several years that a bow thruster might help. The decision to purchase a bow thruster was finally made in 2020. The most difficult step was choosing a location and making the holes for the pipe, as there were no straight surfaces anywhere to make measurements easier.

When choosing a bow thruster, I did not skimp on its power. This was an excellent decision because the end result is excellent. For the bow thruster, I installed two 100Ah AGM batteries in the bow, which also power the anchor windlass.

Motor

I was in Hamburg, stuck in the Maschinraum, or engine room, cleaning the bilge, which could only be accessed through the door on the salon side. Likewise, for engine maintenance, it was the only route if you wanted to, for example, clean the oil filter or change the gearbox oil. There was plenty of room for maintenance, but easier access to the engine is always a good thing. For this reason and with the possibility of lifting the engine in mind, I made a hatch in the bottom of the sump about 70x110cm. In practice, I sawed off a piece of that size from the bottom of the sump, added oak beams around the hole and made a suitable hatch for it. This hatch came into its own when I lifted the engine out in the fall of 2022 for renovation. The engine was moved to my garage where I disassembled it during the winter, used the crankshaft, cylinder block and cylinder head in the machine shop and reassembled the engine using a lot of new parts. The engine overhaul did not go completely according to plan, as the project was hampered by incorrect new parts and missing timing marks.

Summers, past (and future)

Summer sailing has taken us to Åland, but not further, yet. With a few exceptions, we have not made any specific plans for the destinations of our sailing trips, but the weather has dictated where and how far we sail.

So far, the abundance of work has reduced the number of summer sailing days by a lot. You could even say that work has become a habit, fortunately not as big a job as Johanna’s new teak deck from start to finish. Launching has mostly only taken place during Midsummer week, so in practice, sailing has not started before July. Since the preparations have been easy, at least the first week of vacation, there have been about three efficient sailing weeks, as the vacations have typically ended at the end of July.

Another tight schedule was last summer when we sailed Ariadne from Inkoo to Långholm, which is north of Houtskär. The intention was to take Ariadne to her summer port, so that it would be easy to leave for a holiday sailing(s) westward. The trip was completed relatively easily in three days at the beginning of July: Inkoo-Byxholmen-Stenskär-Långholm. The return voyage also took three days. The principle of these transfer voyages was to go far if the weather allowed, and it did.

I must also admit that the Kiel-Hanko sailing was also quite tight in terms of schedule. It turned out to be that way without me noticing, because the boat was in a good mood, there was enough crew and the weather was favorable. Although a few days could have been windier and the temperature warmer than a couple of plus degrees.

The program for the coming summer is - as always before - currently unplanned, although something small is already in the thoughts. You might even consider checking out the waters of our western neighbor, even if it’s just for a quick visit. Especially since the autopilot works quite well based on a few test sails.

Thoughts

Was this worth it? Would I do it again? This question could be debated forever and the answers would vary from an absolute no to an unquestionable yes depending on the day and mood. However, since I have other things to do and I know what a do-or-nothing discussion can do, I will immediately conclude the discussion I started while writing this. Absolutely yes. As Ariadne’s speed increases beyond seven knots, the tinkering is quickly forgotten. Of course, Ariadne is no match for newer boats in speed, but speed is only part of the joy of sailing.

I have often heard that a boat owner has two good days: the day they buy and sell the boat. In my case, that means that at least one good day is still to come. So far, there haven’t been many bad days caused by Ariadne, and most of them seem to be related to engine repairs. There is probably still plenty to do, the most laborious one seems to be renewing the coating on the inside of the water tank. Fortunately, it is not at all acute, and it may well not be done.

Previous -> Ariadne during 2023 - just work